What do you need to know about cnc machining complex parts?

What is the definition of a cnc machining complex part?

CNC machining complex parts refer to the parts that have more structural levels during construction, contain more quality features, have more processes during processing, and have higher precision.

Why are cnc machining complex parts important?

Enterprises that produce these cnc machining complex parts want to occupy more places in the fierce market competition and obtain greater benefits, so they need to strictly control the quality of complex parts during the processing process and focus on improving product quality.

The complexity of the workpiece will have a direct impact on the following factors to a certain extent:

1. Delivery cycle - the more complex the part, the longer the processing cycle will be;

2. Quality -- When you increase the complexity of parts, there may be quality problems, which will increase the cost and delivery time. It can be seen that the cost of achieving more intensive quality requirements will be higher;

3. Manufacturability - If a part is more complex, it is usually less manufacturable, and reducing complexity will mean improving manufacturability.

The current status and existing problems of quality control in the processing of complex parts in world:

For now, CNC machining service companies control the quality of parts processing mainly for individual parts processing procedures. Usually, a production process is divided into multiple working procedures, and then the quality inspection and control of these procedures are carried out separately, or the statistical process of parts is controlled to a certain extent, so as to improve the quality of processed parts; But this is for ordinary products. This is not advisable for complex parts; complex parts will be coupled by multiple factors during the processing process. If only the quality and related characteristics of each part in each process are analyzed separately, there is no Adding the overall analysis will ignore the characteristics between certain two related factors to a certain extent, so that the processed parts will not meet its standards;

To judge whether a part is a complex part, which dimensions need to be paid attention to?

① Part size. Usually, the larger the part size, the higher the cost of raw materials, transportation and processing;

② Holes. Machining deep holes, cavities, taps, etc. requires professional tools, experienced machinists and careful machining settings; these features will be more likely to cause tool breakage; deep holes, cavities, taps with diameters ≥ 10:1; or exceeding 15 individual holes are called high complexity holes. The complexity of parts can be reduced by reducing the aspect ratio and reducing the number of holes;

③Thread. The easiest way to produce threads is through a cnc machine using a preset thread milling program. Usually after the hole is drilled, the thread milling program also needs to take into account the diameter, pitch, thread angle, thread length, etc. of the thread. Standardized threads have off-the-shelf tools and comply with relevant standards; non-standardized threads require special tools and custom thread milling programs; custom, proprietary, obsolete or industry-specific non-standardized threads are high-complexity threads. Selecting only normalized threads reduces this complexity.

④Surface curvature. Curved surfaces are harder to inspect and harder to machine. A curve is defined as a continuous line without any straight segments. Such as circles, ellipses, parabolas, and hyperbolas; compound curves or a large number of bevel processing belong to high-complexity surface curvature; less than 30% of the surface area is angled, which belongs to medium-complexity surface curvature; completely vertical and horizontal walls, and surface area dimensions <10% has a slope, no compound curves, and belongs to the low complexity surface curvature. Reducing the number of angled surfaces reduces this complexity.

⑤Wall thickness. Wall thickness ≤ 0.5mm (metal) or ≤ 1mm (plastic), parts with this wall thickness are high-complexity parts; increasing the wall thickness of components and reducing the wall thickness of mating parts can reduce this complexity;

⑥Tolerance. Tolerances have the greatest impact on part complexity. Close tolerances mean more precise machining, stricter quality control measures, more sophisticated measuring equipment, and often more inspections. Any tolerance <0.002mm belongs to high complexity tolerance; all tolerances >0.002mm belong to medium complexity tolerance; all tolerance values >0.06mm belong to low complexity tolerance. My advice is to use tight tolerances only when absolutely necessary.

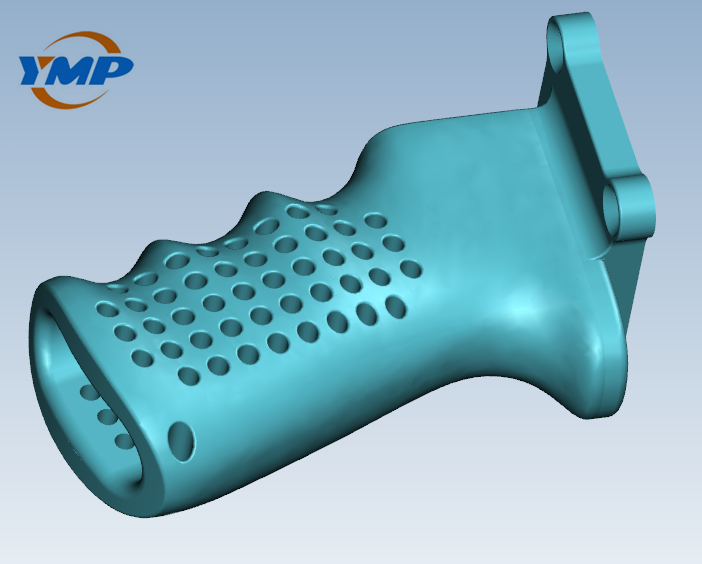

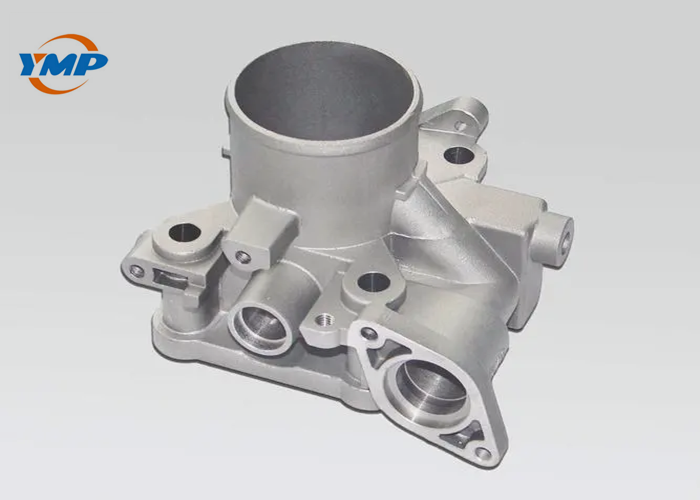

We will show you low-complexity parts, medium-complexity parts and high-complexity parts with pictures:

(Low complexity parts)

(Medium complexity parts)

(High complexity parts)

Shenzhen YiXin Precision Metal And Plastic Ltd. has nearly 20 years of experience in CNC machining, and has been deeply involved in high-end fields that have high technological requirements for metal parts, such as car racing modification, medical equipment, high-end audio, robotics, aerospace etc.;

We have nearly a hundred professional engineers and machining experts, providing you with a series of turnkey services from design drawings-mass production and processing-quality inspection-factory delivery. Welcome to contact us.

- Pre:Basic components of CNC lathe 2023/10/19

- Next:Advantages and Disadvantages of Wireless Charging 2019/7/1